When it comes to measuring the size of particles in a sieve, two common metrics are used: mesh size and micron size. Mesh size refers to the number of openings in a square inch of screen, while micron size measures the size of individual particles. Understanding the conversion between these two metrics is essential for various industries, including pharmaceuticals, food processing, and mining.

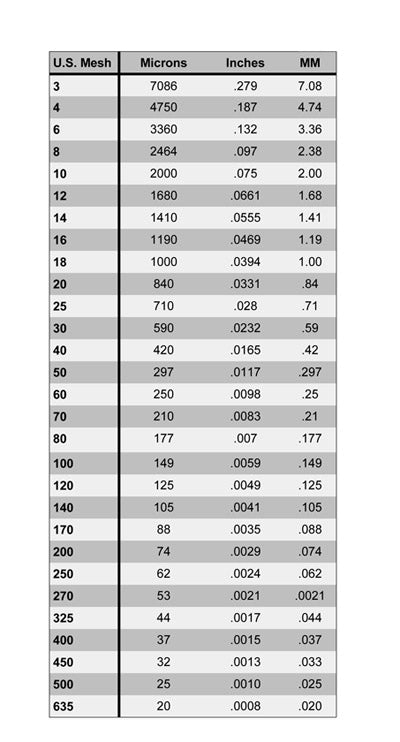

Converting mesh size to micron size can be done using a simple formula. For example, a 100-mesh screen has 100 openings per inch, which translates to 154 microns. To help you easily convert between mesh size and micron size, refer to the following conversion chart:

Mesh Size To Micron Conversion Chart

| Mesh Size | Micron Size |

|---|---|

| 40 | 420 |

| 60 | 250 |

| 80 | 177 |

| 100 | 154 |

Applications of Mesh Size and Micron Conversion

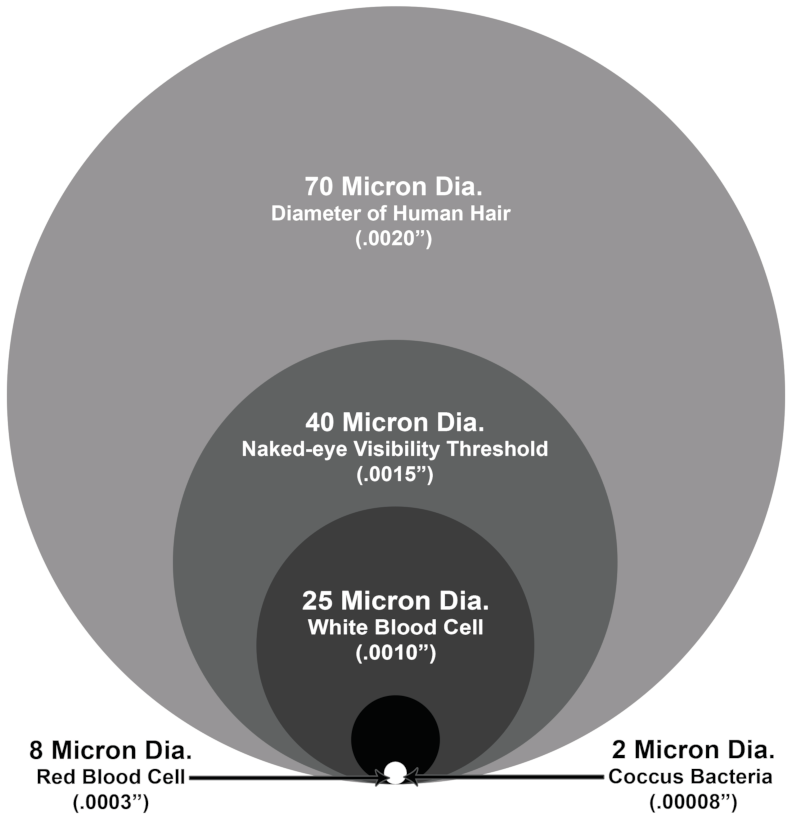

Understanding mesh size to micron conversion is crucial for various applications. In pharmaceutical manufacturing, the size of particles in medications can impact their efficacy. In food processing, the size of particles in ingredients can affect the texture and taste of the final product. In mining, the size of particles in ores can determine the efficiency of extraction processes. By using the conversion chart and applying the correct mesh size or micron size, industries can ensure optimal results in their processes.

By providing a comprehensive overview of mesh size to micron conversion and its applications, this article aims to equip readers with the knowledge needed to make informed decisions in their respective industries. Whether you are a scientist, engineer, or manufacturer, understanding the relationship between mesh size and micron size is essential for achieving desired outcomes.

Download Mesh Size To Micron Conversion Chart

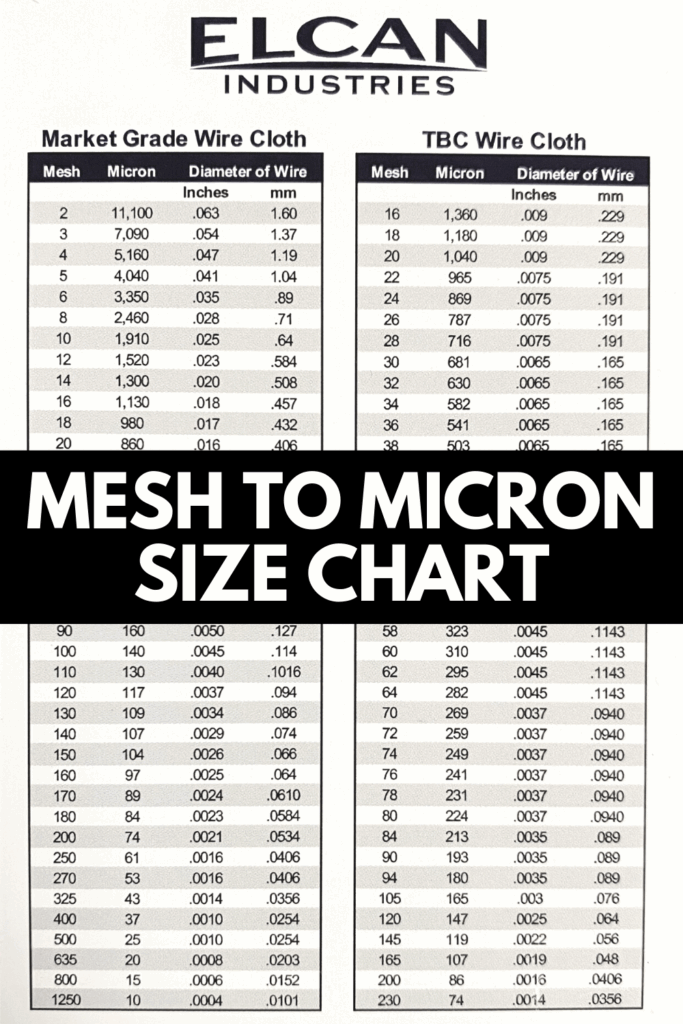

Mesh To Micron Chart Micron Size Elcan Industries 41 OFF

Different Mesh Sizes And Mesh To Micron Conversion 53 OFF